Battery Chargers

Battery chargers

This article is the natural follow up to the “Battery Box” project. And thus the next episode of the electrickery thread –

http://www.4x4community.co.za/forum/…ry-for-camping

The original thread was written in 2014, based on technology of the time. We all know the pace of technological progress, and the game has changed a lot since then !

Back to basics for a moment – HOW do you want to charge your battery ? You have three options:

1. From the alternator

2. From a PV panel

3. From a 220V power source

1) Alternator

This is the true origin of power at a camp site – running equipment from your vehicle battery. But this leads to flat batteries and jumper leads. And thus the concept of the “second battery” was born. Charging this second battery has been a hot topic ever since, with many options and many more opinions. This article will concentrate on the “more accepted practices”.

– Batteries in Parallel – two batteries are connected in parallel with no switches or other equipment, to assist in the charging process. Sometimes the user would install a manual switch to be able to disconnect the batteries, to prevent draining the starter battery. For this approach a “standard cranking” battery should be used, preferably the same make and size as the vehicle battery. This is needed due to the behaviour of two batteries in parallel, a topic in its own right.

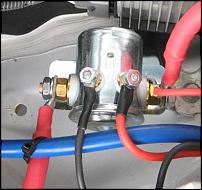

– Cole Hersee solenoid – this is much the same as the previous, except that the solenoid connects and disconnects the second battery automatically as the ignition is switched. This is more convenient, but has no more charging benefit than the former.

The problems started when “deep cycle” batteries were introduced, requiring 14,5V to charge fully. While most alternators peak at around 13,8 to 14V, thus these connection methods can not charge a battery “full”.

– DC-to-DC chargers – this box of tricks changed the game forever ! Basically it takes in “energy” at 13 to 14V (whatever the alternator can deliver), it then increases the voltage to obtain the 14,5V required for a full charge of the deep cycle battery. Most modern DC-2-DC chargers provide the following:

– It automatically starts charging when the primary voltage increases above 13V, which happens when the engine is started.

– It automatically stops charging, and disconnects the 2nd battery from the primary, when the primary voltage drops below 12,8V, this happens shortly after switching off the engine.

– It limits the charging current as per the unit specification, and gradually adjusts the charging voltage as the battery “state of charge” (SOC) increases. Thus an “empty” battery could be charged with a voltage of around 13V, as the State of Charge (SOC) increase the charging voltage increases to about 13,8V. For the last 10% of the charge the charging voltage is gradually increased to 14,5V, after which it drops back to about 13,8V “float charge”.

– Some chargers, such as the 12A HCDP, have a “load” output. These typically have a slightly lower charge rate, and then supply additional current from the alternator directly to the load. This is beneficial in that the recharge time of the battery is not extended by the load taking some of the charge current.

2) PV solar regulators

These “chargers” are called “regulators”, and are split into two main groups:

1) Pulse Width Modulating (PWM)

2) Maximum Power Point Tracking (MPPT)

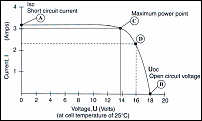

A deeper understanding is required of PV solar panels to appreciate the differences between the two types of regulators. In laymen’s terms a PV solar panel provides energy on a “V vs. A” graph, with the maximum voltage (Voc – open circuit voltage) at 0A and the maximum current (Asc – short circuit current) at 0V, both totally impractical. The “working” range for the PV solar panel is in the zone around “C”, in the graph below –

As an example, the values for a 100W panel may look as follows:

Open circuit voltage(Voc) – 22.2V

Optimum operating voltage(Vmp) – 18V

Short circuit current(Isc) – 6.58A

Optimum operating current(Imp) 5.56A

Maximum power at STC (pm) 100 Wp

Dimensions: 1120mmx670mmx35mm

NOTE – as this article is aimed at the 4×4 market the values provide relate to a 12V battery system and associated equipment. The theory remains similar for larger installations, though the battery voltage is stepped up to 24 or 48V, with the associated changes in the equipment.

The supply voltage of the PV solar panel is in excess of the 14,5V required to fully charge the battery. Depending on various factors the panel voltage may vary between 16 to 19V when charging the battery. The two types of regulators “regulate” the available energy to ensure the battery is charged at a safe rate.

– PMW – In the crudest possible terms, a PWM regulators switches ON and connects the full voltage to the battery, then OFF. By modulating the times for the on and off cycles the battery sees an effective voltage applied over the poles. A very simple, yet robust solution, to charge the battery without damaging the battery. The downside is that under optimal sun conditions not all energy can be used, as the battery will be damaged if 16 to 19V is connected to it for prolonged periods. More about this cost vs. efficiency later.

An example of a PWM regulator is the SAKO unit from 4x4Direct – http://www.4x4direct.co.za/regulator…l-display.html

– MPPT – this unit takes it a step further and monitors the available energy, and takes “just enough” energy from the panels to ensure the supply voltage remains on point “C” on the graph above. By continually tracking the maximum power from the panel and doing micro adjustments to the energy taken from the panel it extracts the maximum power from the panel. Under high sun conditions this means a very high yield of energy from the PV solar panels. This comes at a cost, both financially and in terms of the energy used by the controlling circuit. More about this later.

An example of a MPPT regulator is the Victron unit from 4x4Direct – http://www.4x4direct.co.za/regulator…oller-15a.html

HI-JACK ALERT – I have been USING the Victron unit at home for the last 2 years.

At the peak of load shedding I installed the following system at home, yes most parts bought from 4x4Direct:

– 100W PV solar panel

– Victron 15 Regulator (the unit referred to above)

– MeanWell inverter

– 100A.h battery

This carried us through a few load-shedding sessions. Then I copied my neighbour and did a whole house 12V light installation (in addition to the 220V lights). Since then we have hardly ever used the eskom lights. Each night the battery is used down to about 50 to 60% SOC. Each day the PV solar panel and Victron regulator recharges the battery. Fair to say I have TESTED the system under all weather conditions.

4x4Direct have now afforded me the opportunity to TEST the PWM unit. J More about the tests a bit later….

1 + 2) Alternator + PV solar regulators

Time to stir up the pot a bit ….

So you now understand the options regarding charging from the alternator … DC-2-DC charger and you are SORTED, as long as you drive enough to keep the battery charged.

And if you are the type that parks of for days, then you get a PV solar regulator and you are sorted as long as the drinks last.

BUT, if you are the type that goes to Kgalagadi. Well, you need to do a Kgalagadi trip to truly understand this. Out of the camp most of the time, driving SHORT distances. And before long you don’t have enough time in camp to use your PV solar system, nor are you driving enough to charge the battery.

“Ctek 250 S” understood this, and provided a single unit to the market to provide:

– A DC-2-DC charger;

– A PV solar regulator; AND

– It switched automatically between the two !

This third function is particularly important when your stops are around these cute puppies, especially when they are 2m from your window !! Not as if you want to walk to the back of your vehicle to flick a few switches to change from alternator to solar charging …. –

BUT, sadly so, the Ctek prices have kept on increasing, again and again. This in an era where electronics prices either comes down or offers more for the same cost. The Ctek is still a brilliant product !! But its price has opened the market for the competition. J

BUT, sadly so, the Ctek prices have kept on increasing, again and again. This in an era where electronics prices either comes down or offers more for the same cost. The Ctek is still a brilliant product !! But its price has opened the market for the competition. J

4x4Direct has been testing the WRND unit for some time, and has now afforded me the opportunity to test it. J J

http://www.4x4direct.co.za/dc-to-dc-…olar-mppt.html

The WRND unit provides the following :

– 20A DC-2-DC charger

– MPPT PV solar regulator

– It automatically switches between the two

– All this for less than a third of the cost of the Ctek !

3) 220V power source

Charging from the alternator and/or PV solar is fine when on holiday, but how to keep the battery charged at home ?

Motorcyclists have pondered this question each winter for decades. Optimate was probably one of the first chargers for this requirement. Next “maintenance chargers” were provided to car collectors.

Both of these were aimed at “starter batteries”.

Today the wide array of batteries used by campers have caused challenges for charger manufacturers. Not all batteries have the same requirements from a maintenance charger, i.e. different float voltages etc.

Units such as the National Luna charger caters for different battery types – http://www.4x4direct.co.za/home-char…y-charger.html

Using BH plugs it is possible to switch between the different chargers and to compare charging rates and performances under similar sun and SOC conditions ….

Using BH plugs it is possible to switch between the different chargers and to compare charging rates and performances under similar sun and SOC conditions ….

Posted with permission from ChrisF

4 July 2017