Corrosion Comparison Test

For many years I wondered what the best way is to treat rust, especially in areas where you cannot always remove all the rust..

One thing that never made sense is how manufacturers can advice people to use water based products as a solution to trust. Rust is formed on a metal when oxygen and water is present. If you can remove one of these 2 elements you will not have rust.

Especially when restoring or fixing old cars. You always have rust which starts to form inside the doors, fenders, A-Pilars, etc. If you can treat and stop, or slow down, the rust you can extend the life of the car without having to cut and weld.

The last thing you need is a product with false promises. Imagine you trust the online reviews and trust a product, you paint all the difficult to reach spaces inside a car, just to find that the product actually excellerated the rust, not stop it. If you treat rust inside a car you need to be sure that it will be stopped or slowed down.

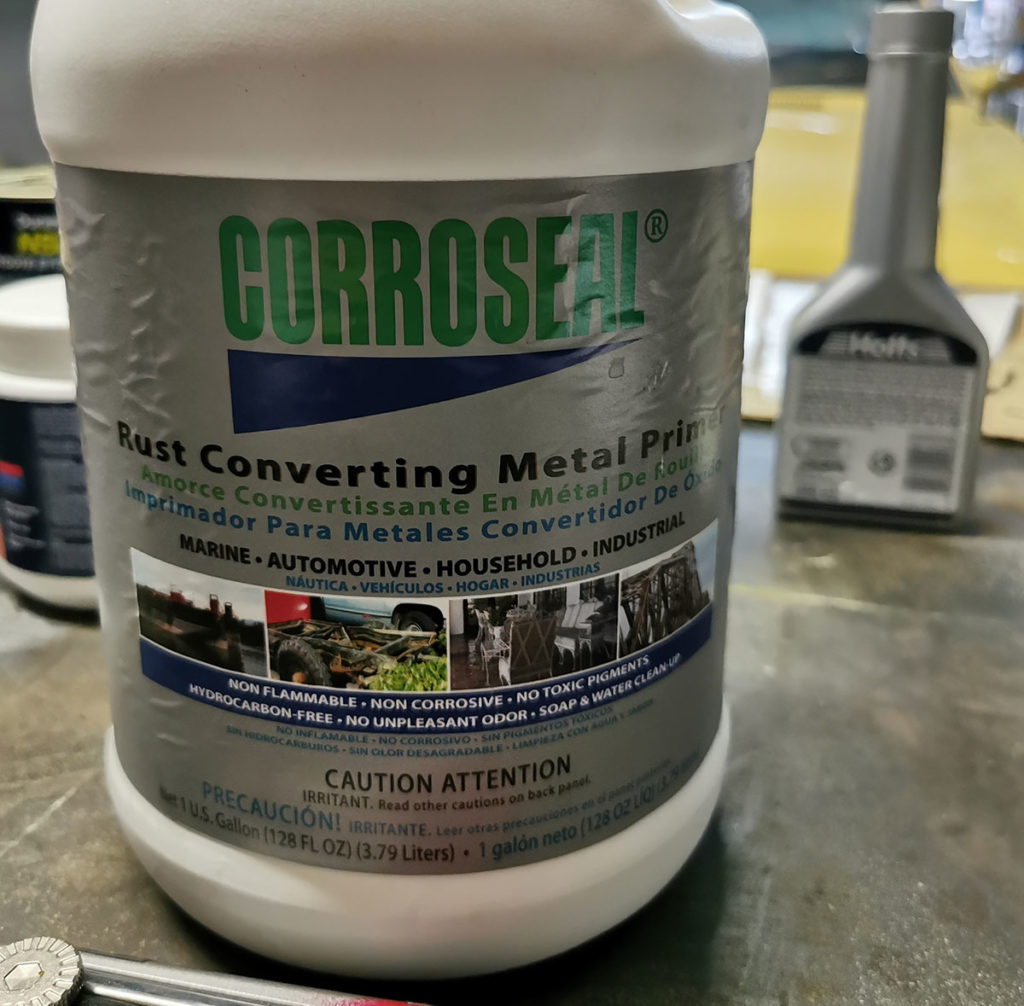

I was looking for a good rust converter and one product kept on showing in the top 3 results of online reviews. I decided to import some of it as I could not find any in South Africa. It was touted as the best rust converter on so many web sites that I did not even think twice. When I received it I immediately started to treat my old Ranchero which I know I can only start restoring a year from now and I just wanted to slow the rust down during the waiting period.

To my surpise I saw light brown corrosion forming in the area which I treated the next day and I realised this product was nothing different from other water based corrosion treatments.

So I bought 10 other paints, primers and rust converters. I was looking for products which claimed that they convert rust, prevent rust, is a primer and top coat in one. The typical “Direct to Rust” solutions.

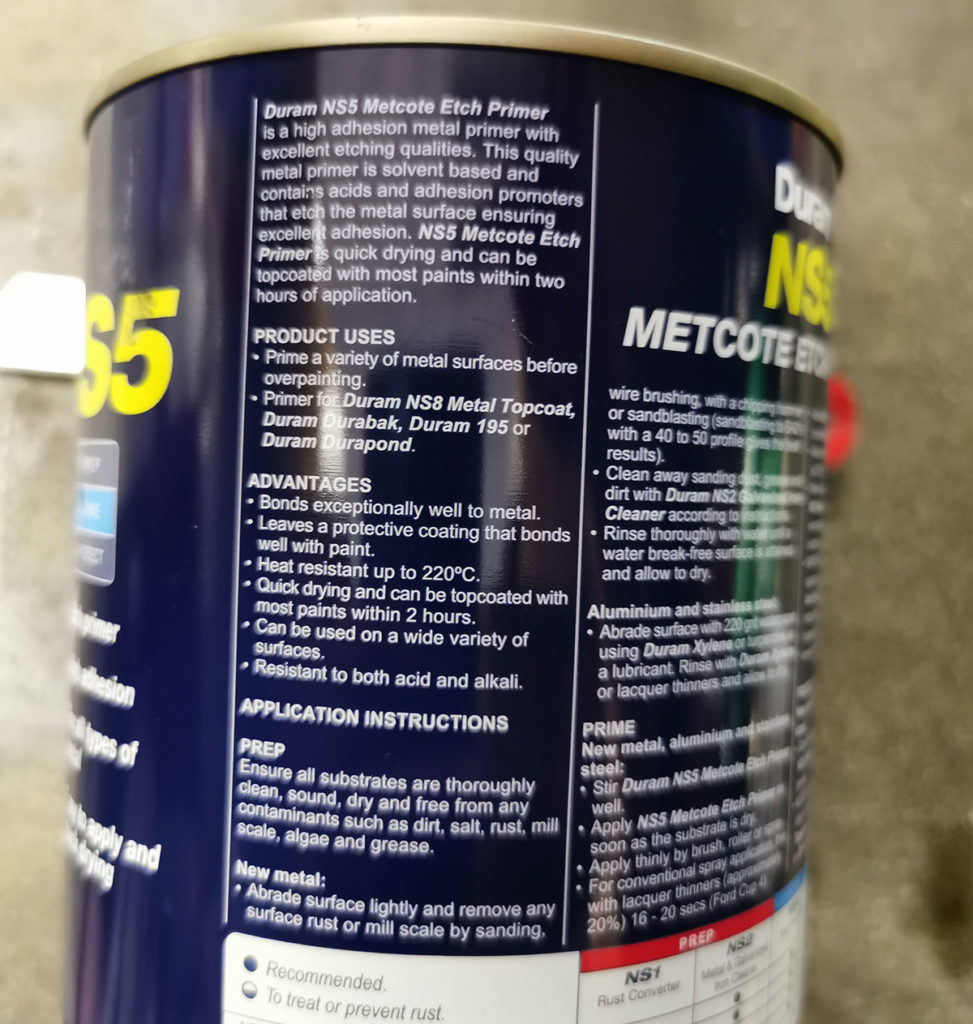

The only exception was Duram NS5 etch primer. It is my favorite etch primer. It does not claim to prevent existing rust and it clearly state that it is only a primer and needs a top coat to be effective. Yet it outperforms many of the so called rust inhibitors.

The products used in the test were (I added their claim in brackets):

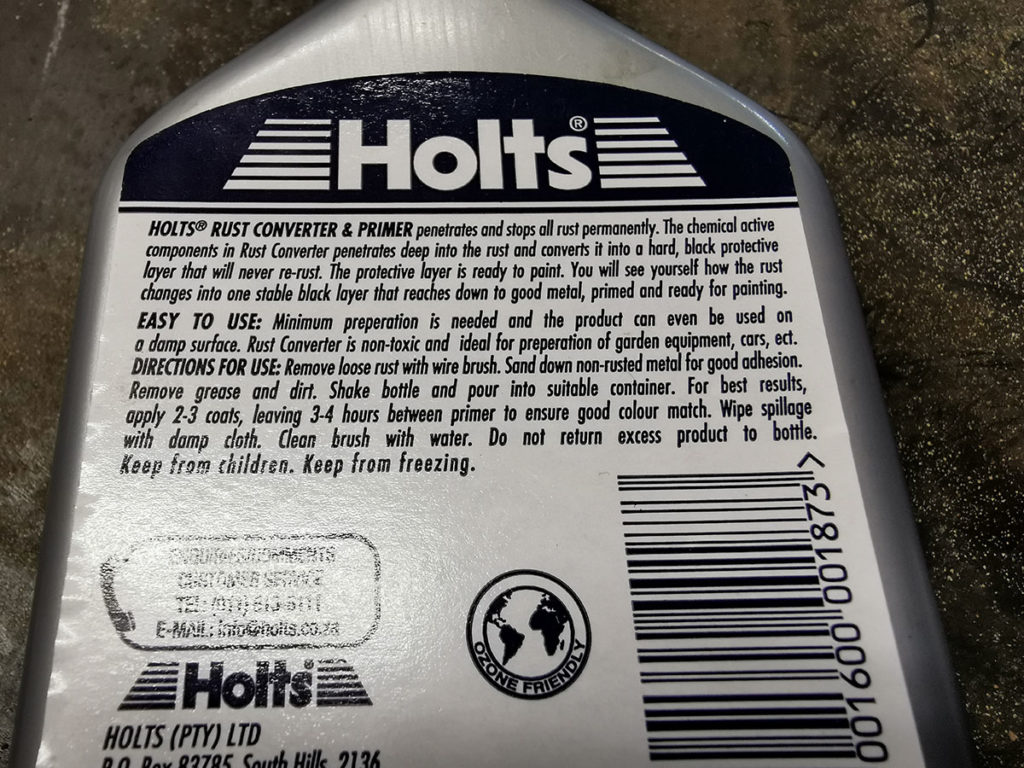

- Holts Rust Converter and Primer – (Penetrates and stops all rust permanently)

- Tectyl Multi Purpose – (Is a versatile rust preventive for automobile..)

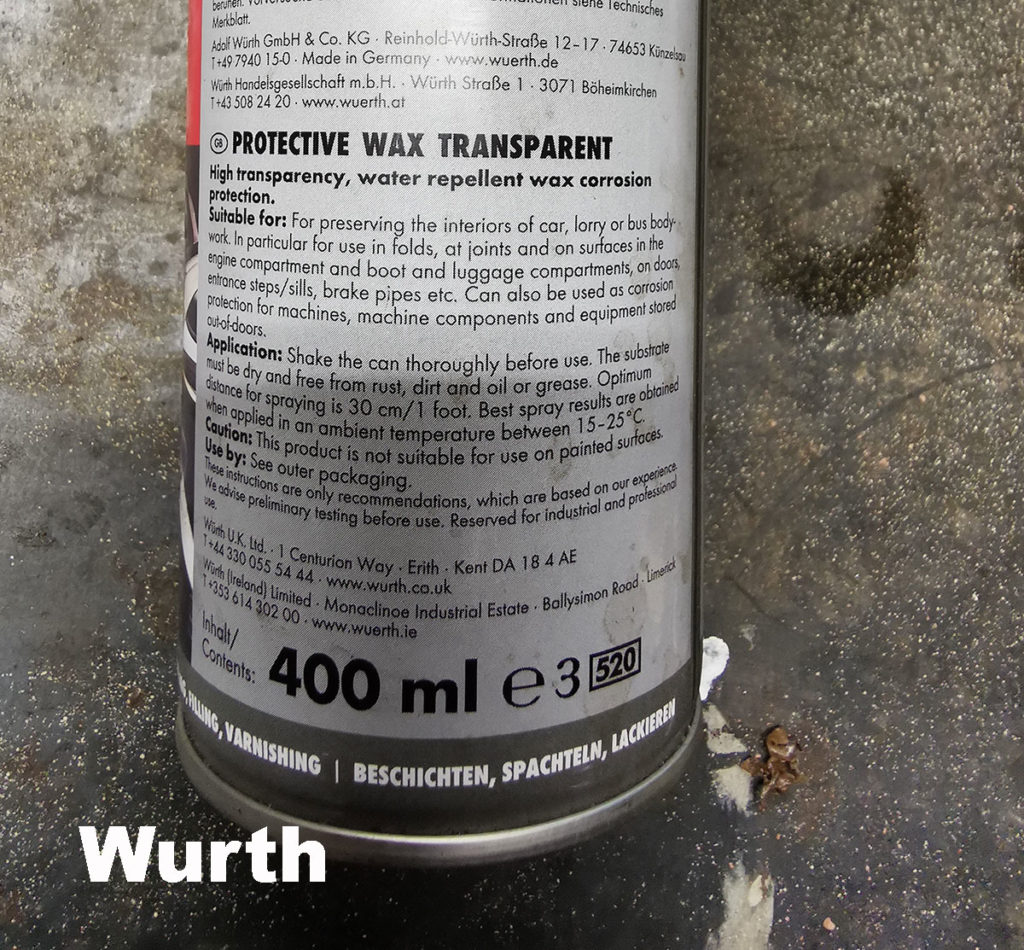

- Wurth Protective Wax – (Can also be used as corrosion protection for machine components and equipment stored ou of doors)

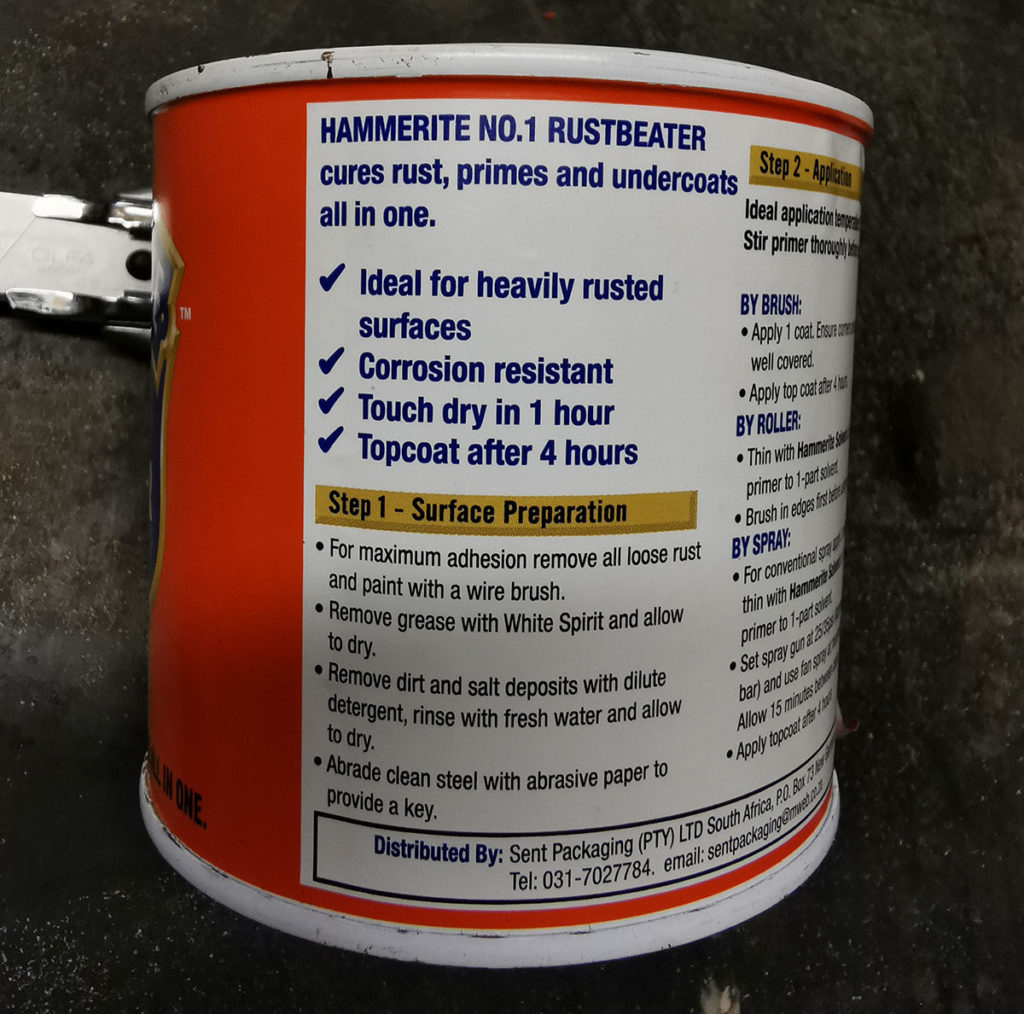

- Hammerite Rustbeater – (Cures rust, primes and undercoats all in one)

- Hammerite Direct to rust metal paint – (perform as primer, undercoat and topcoat in one.)

- Rust Rite all in 1 metal coating – (Direct to rust, NO Primer – No undercoat – No Rust)

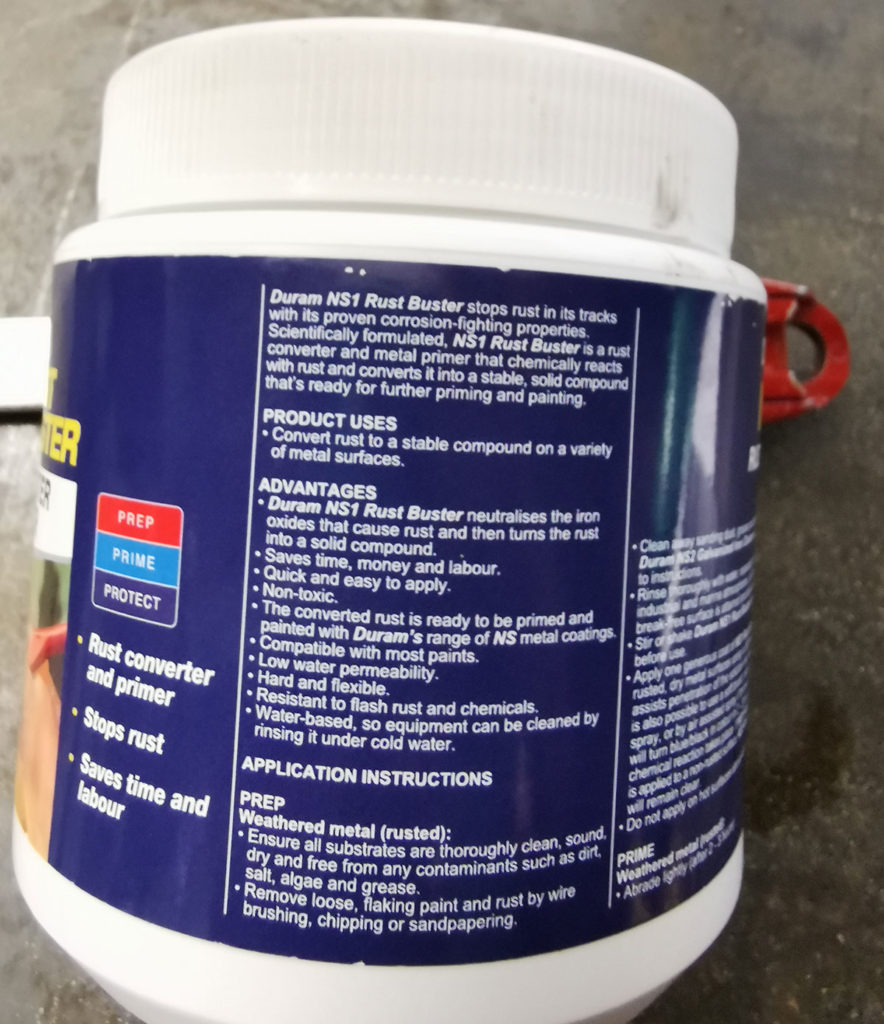

- Duram NS1 Rust Buster – water based – (Stop rust in its tracks with its proven corrosion fighting properties)

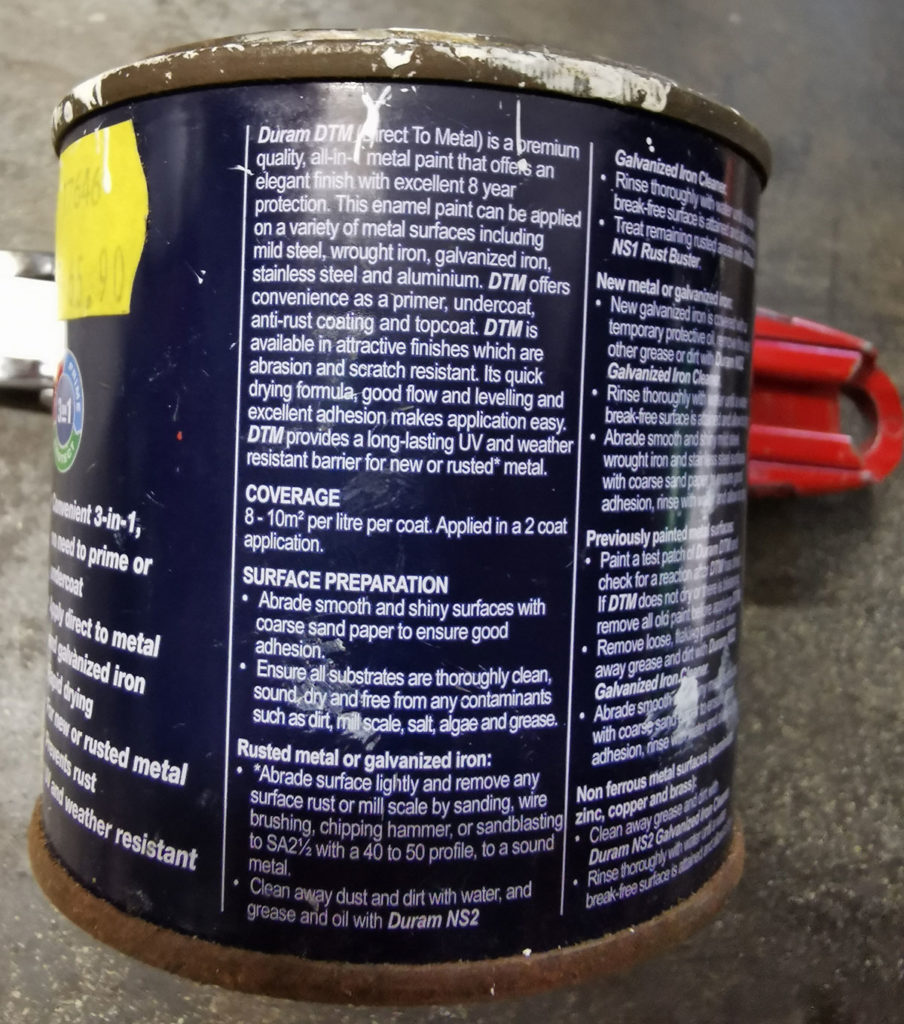

- Duram DTM Direct to Metal – (convenience as primer, undercoat, anto-rust coating and topcoat)

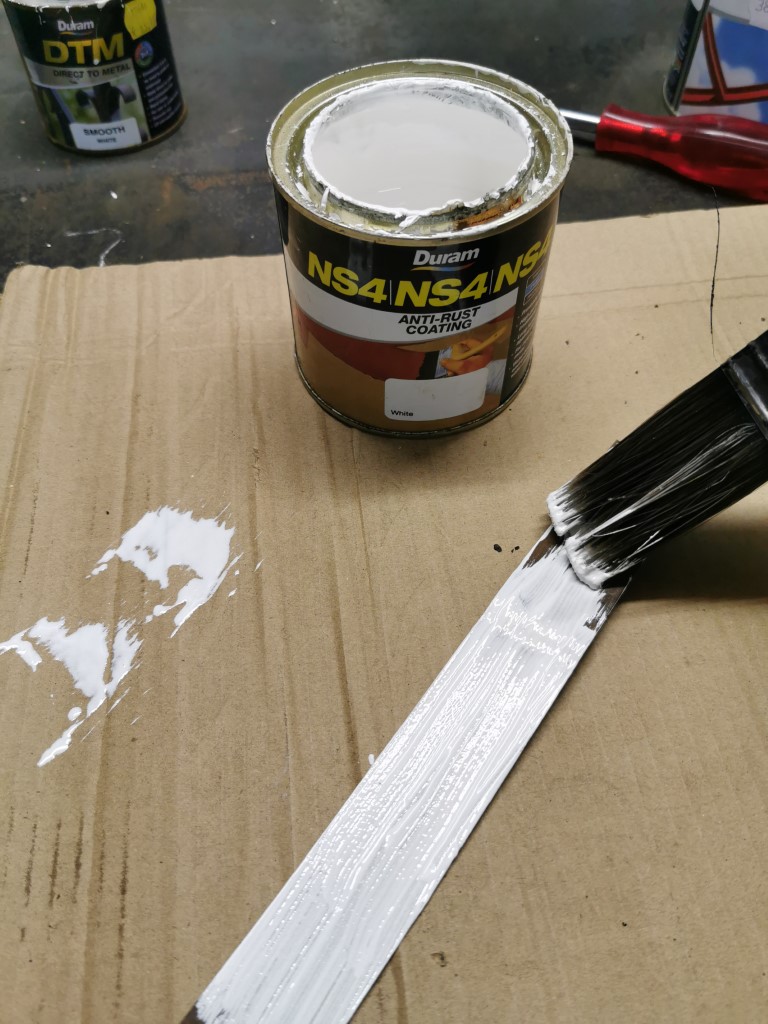

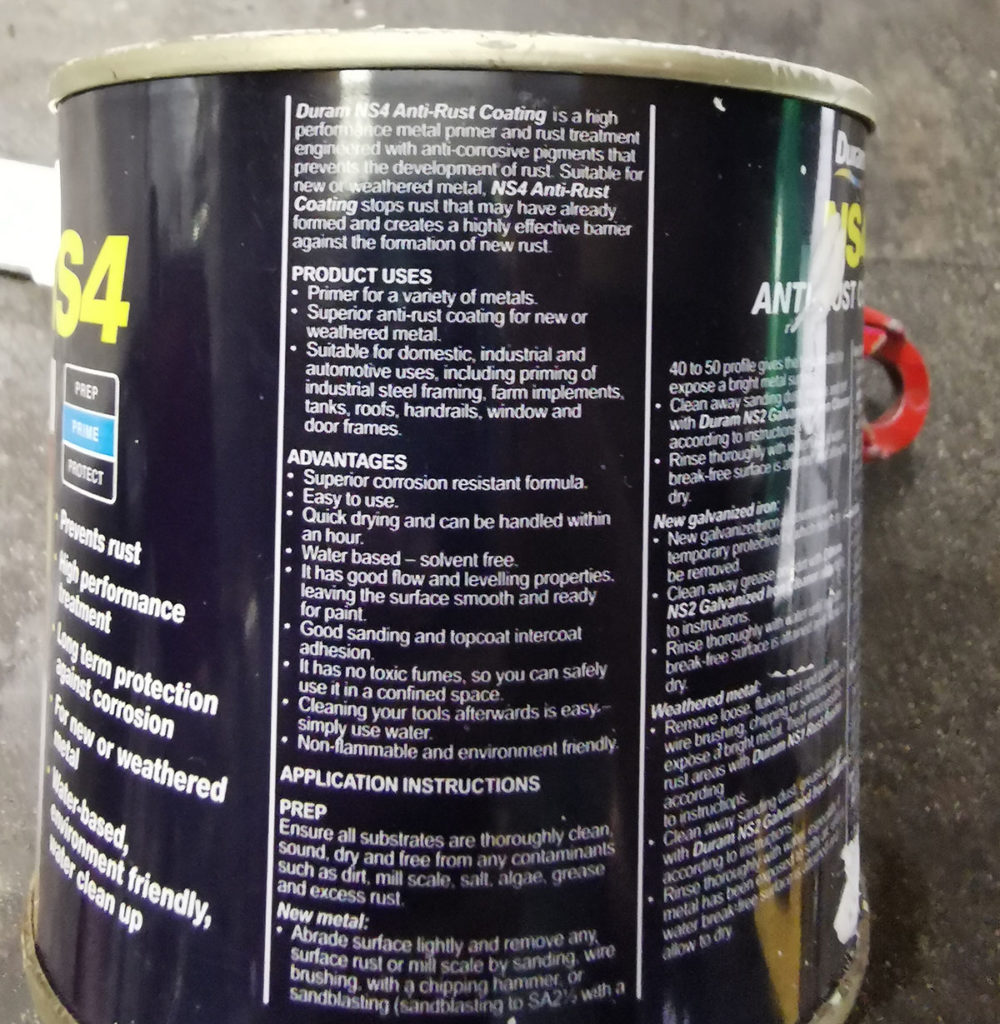

- Duram NS4 anti rust coating – water based ( stops rust that may have already formed and creates highly effective barrier against the formation of new rust)

- Duram NS5 Etch Primer – (high adhesion metal primer with excellent etching qualities.)

- Corroseal Rust Converting metal primer – (Rust converting metal primer)

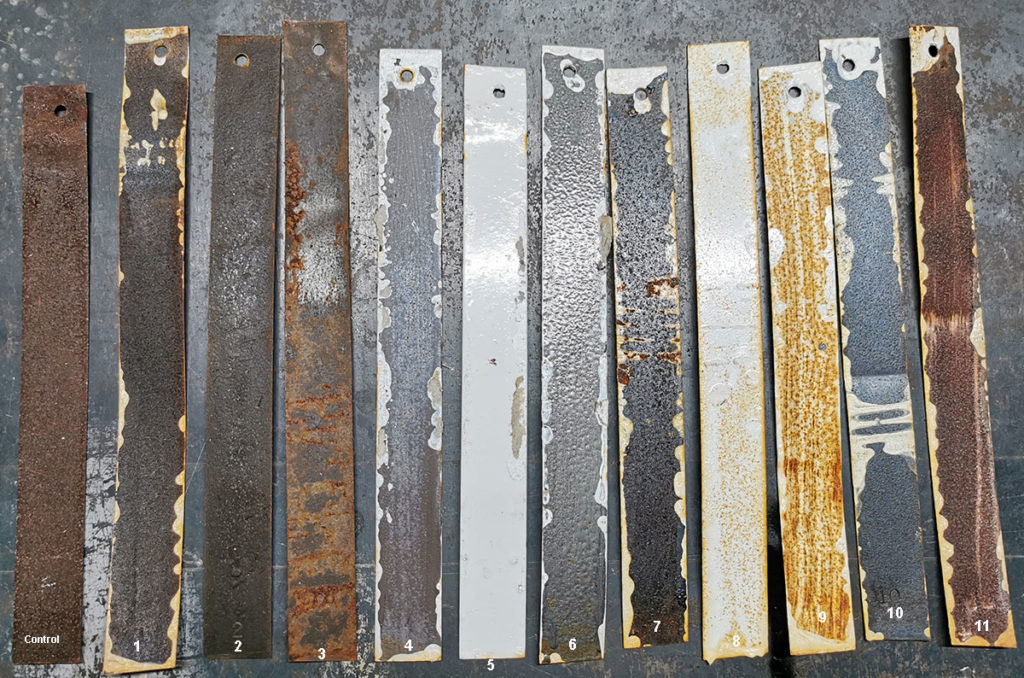

1 – Holts

2 – Tectyl

3 – Wurth

4 – Hammerite Rustbeater

5 – Hammerite Direct to Rust

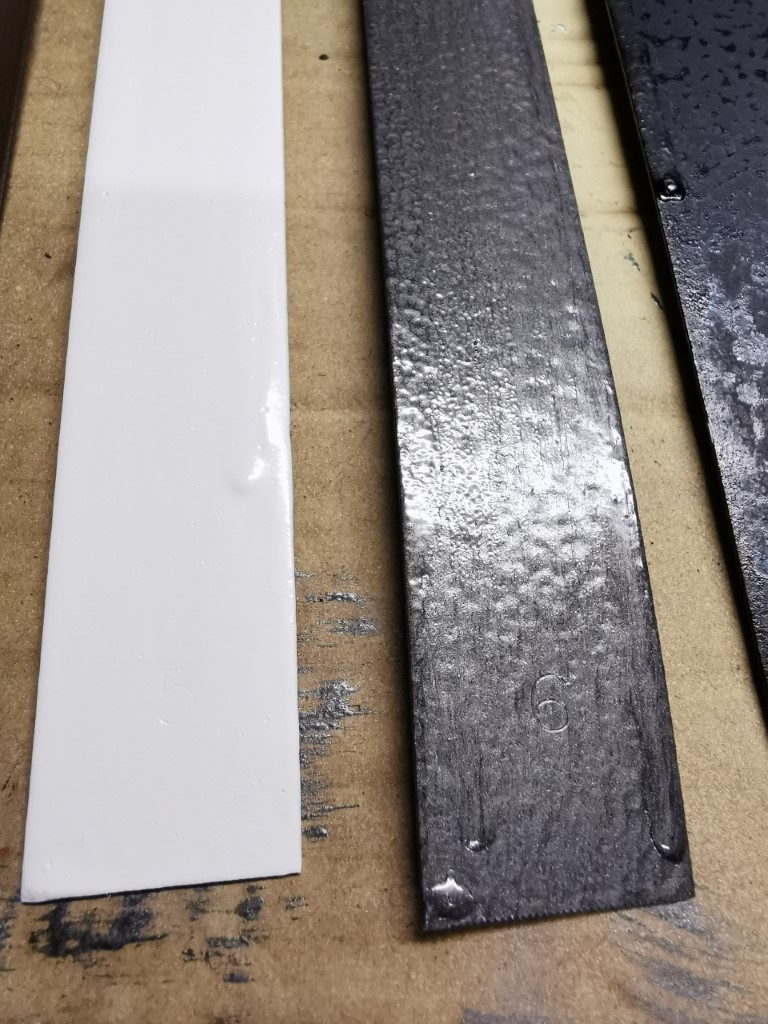

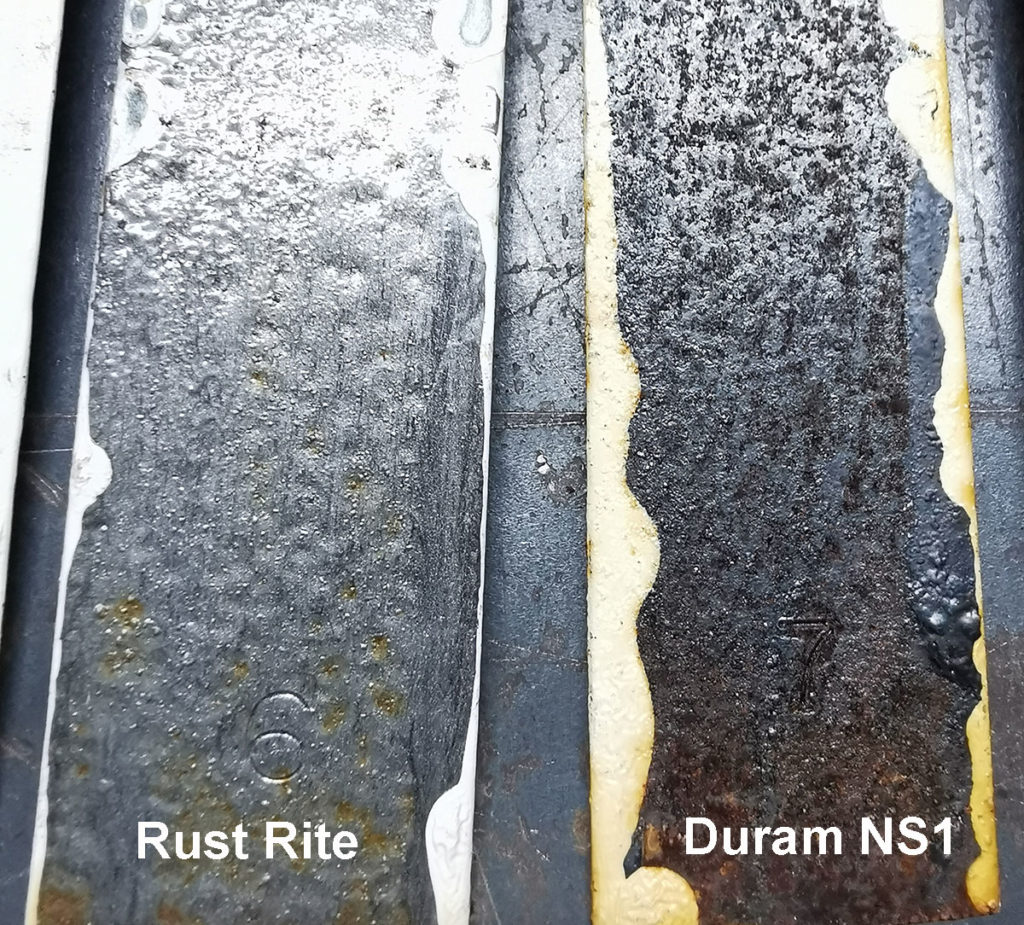

6 – Rust Rite

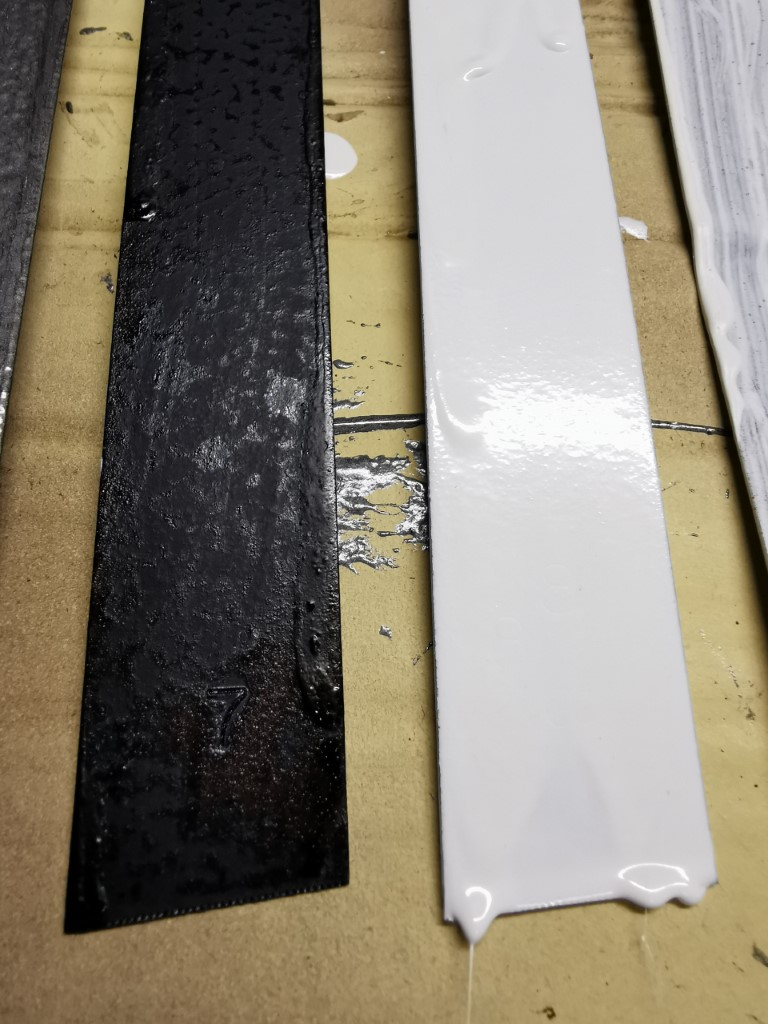

7 – Duram NS1

8 – Duram DTM

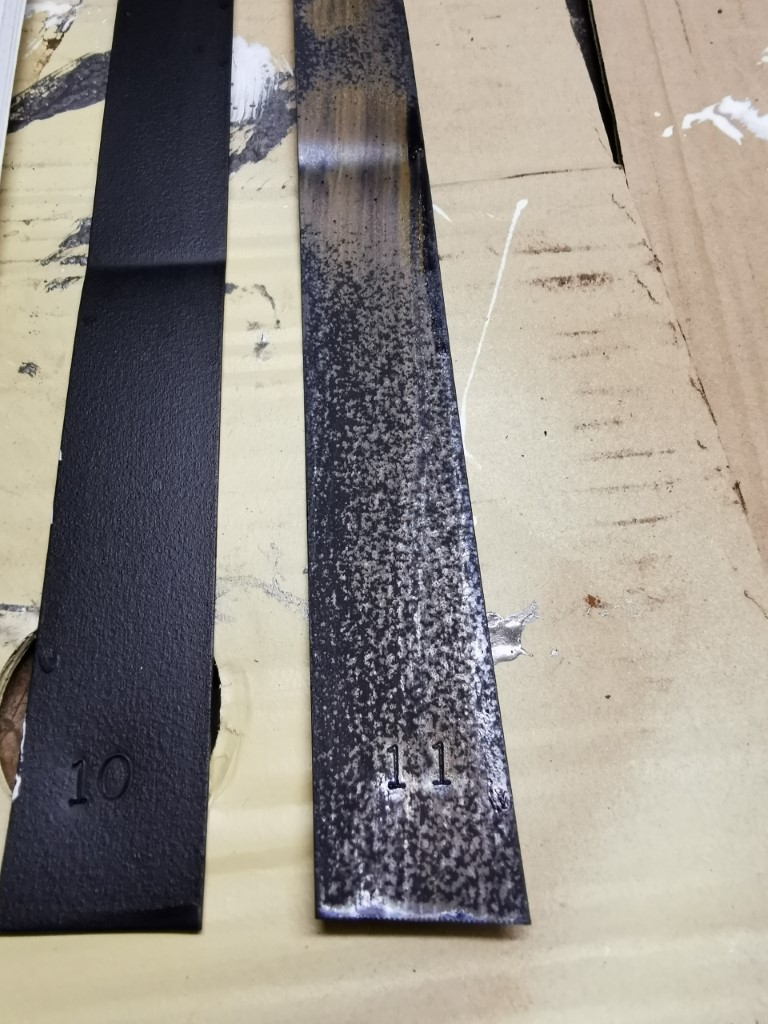

9 – Duram NS4

10 – Duram NS5

11 – Corroseal

Test 1

I used 12 strips of slightly rusted metal. The one strip is the control. The other strips were numbered by means of a number punch from numbers 1 to 11.

On 28 May 2020 I cleaned each strip as per instructions. I used the minimum requirement for cleaning. Thus if instructions permitted steel brush cleaning only I did it. With DTM I cleaned it more as DTM says surface must be very clean, they do not claim that you can paint direct to rust. Also washed all strips with Thinners before applying products.

I then applied the products as per instructions on both sides of the strips.

I applied one layer on each strip except where a product instructs otherwise in their instructions. Holts was the only one which said you must do 3 layers, so I did.

Then let them hang until the next day.

On 29 May 2020 I painted the one side with 2 layers of normal white enamel paint. Most of the products claim to be a primer and undercoat, thus they were not designed to be used without a top coat. I painted the top coat to all products, even if the products claims to be a top coat on its own. The idea was to give each one maximum protection by using 2 coats of enamel.

Tectyl and Wurth did not receive the enamel paint on the back as both of them are waxes, enamel wont work well with wax.

I drilled a hole in each strip and made a wooden frame to screw the strips on to. The frame was then placed on the roof of my house. My house is about 300 meters from the lagoon, this a very corrosive environment and the ideal place to do corrosion tests. This time of year we get fog almost every evening, thus the metal gets wet just about every evening.

Results:

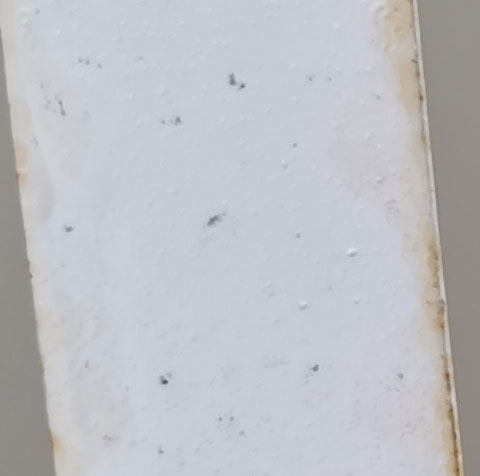

13 June 2020

1 Holts

2 Tectyl

3 Wurth

4 Hammerite Rustbeater

5 Hammerite direct tust

6 Rust Rite

7 Duram NS1

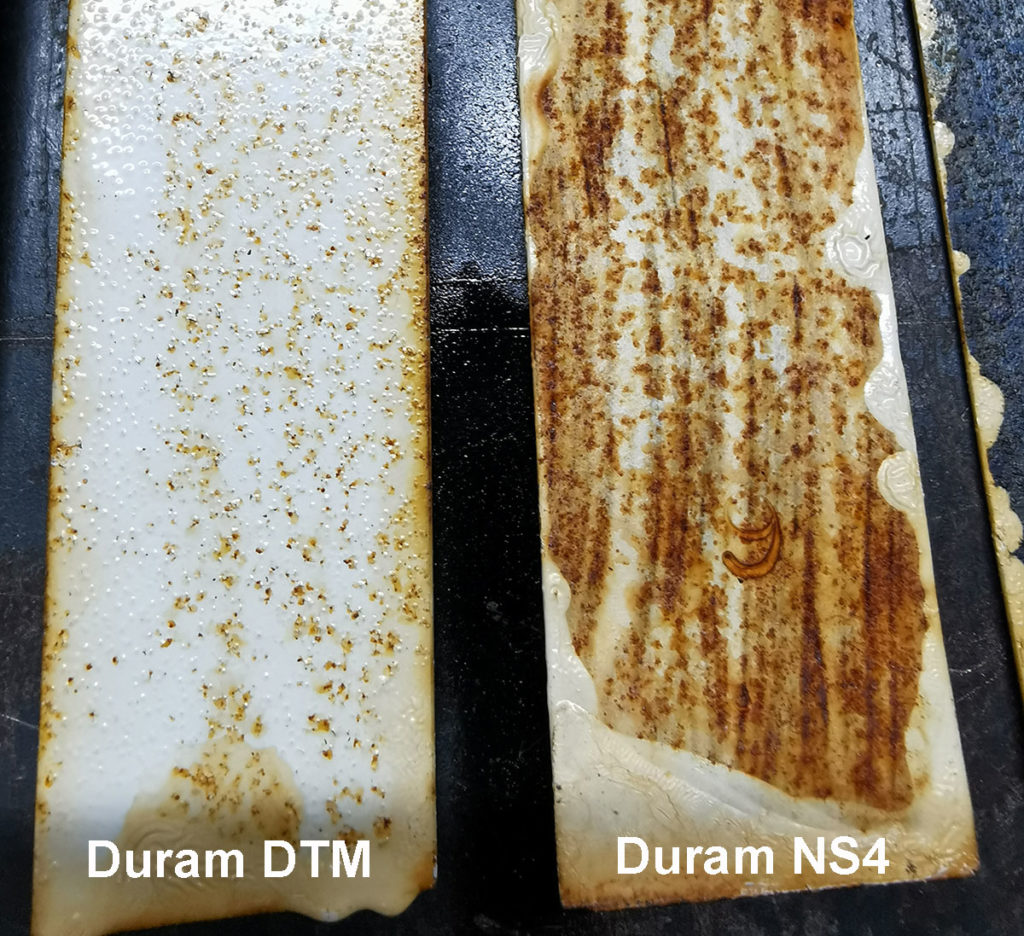

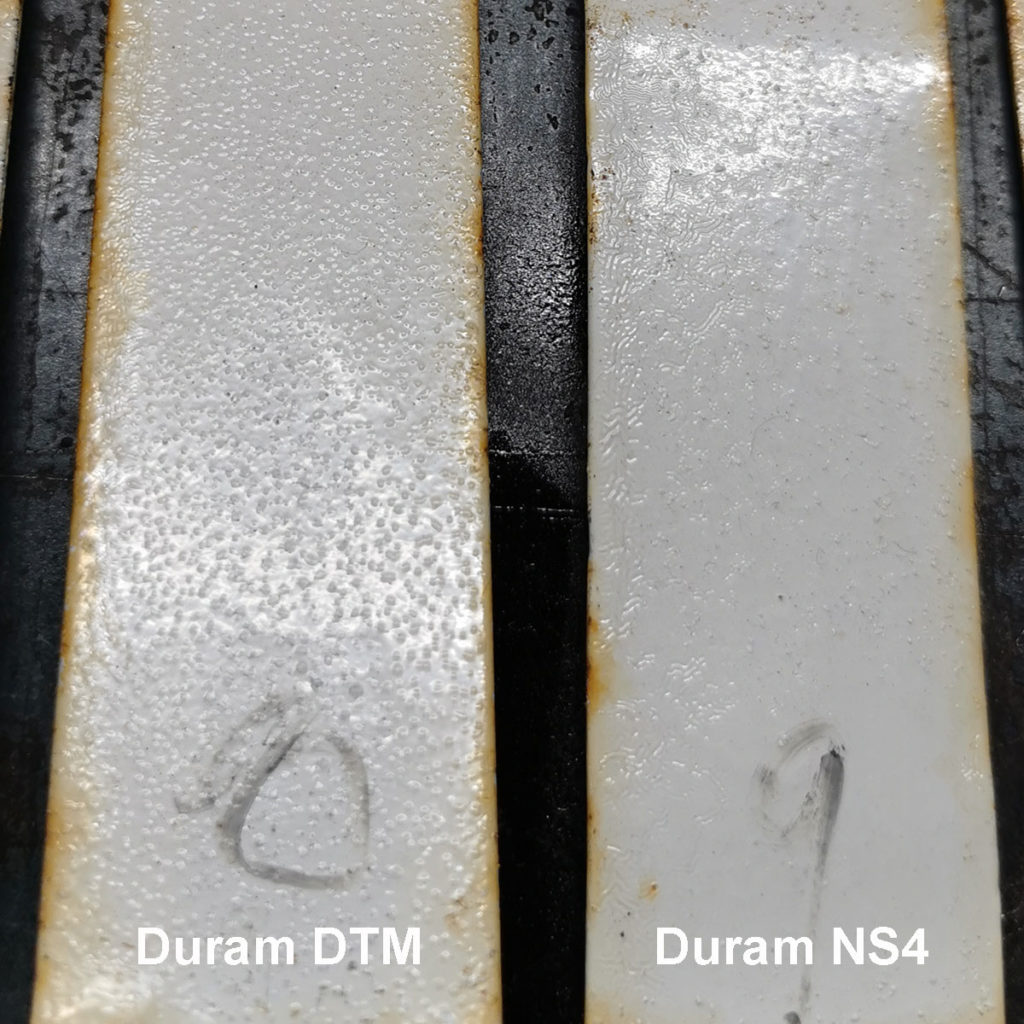

8 Duram DTM

9 Duram NS4

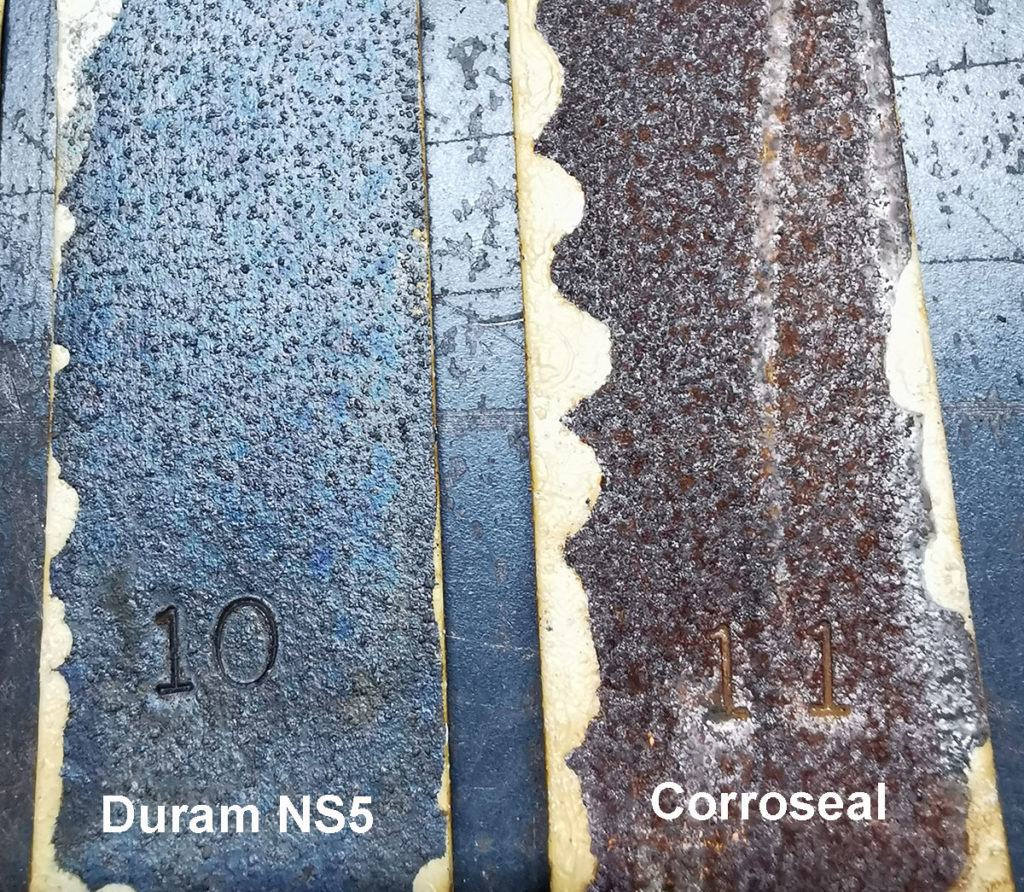

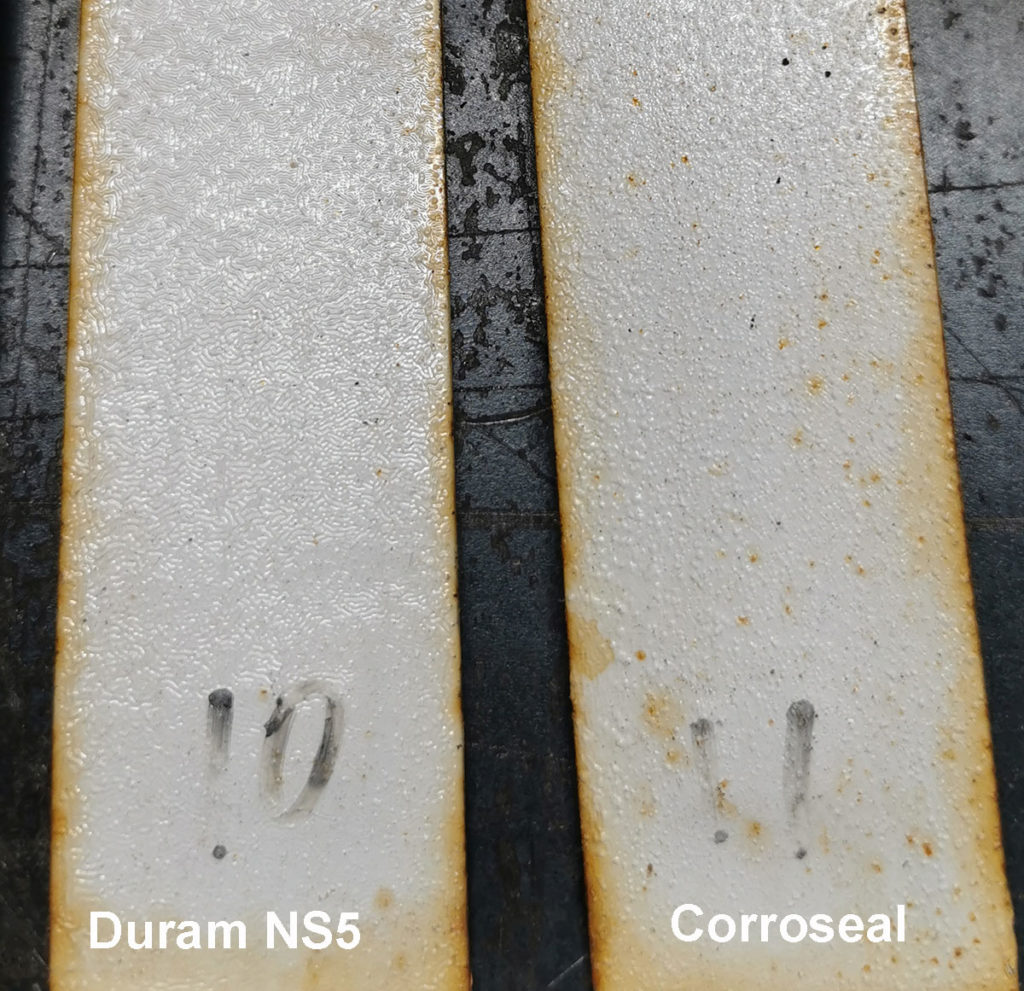

10 Duram NS5

11 Corroseal

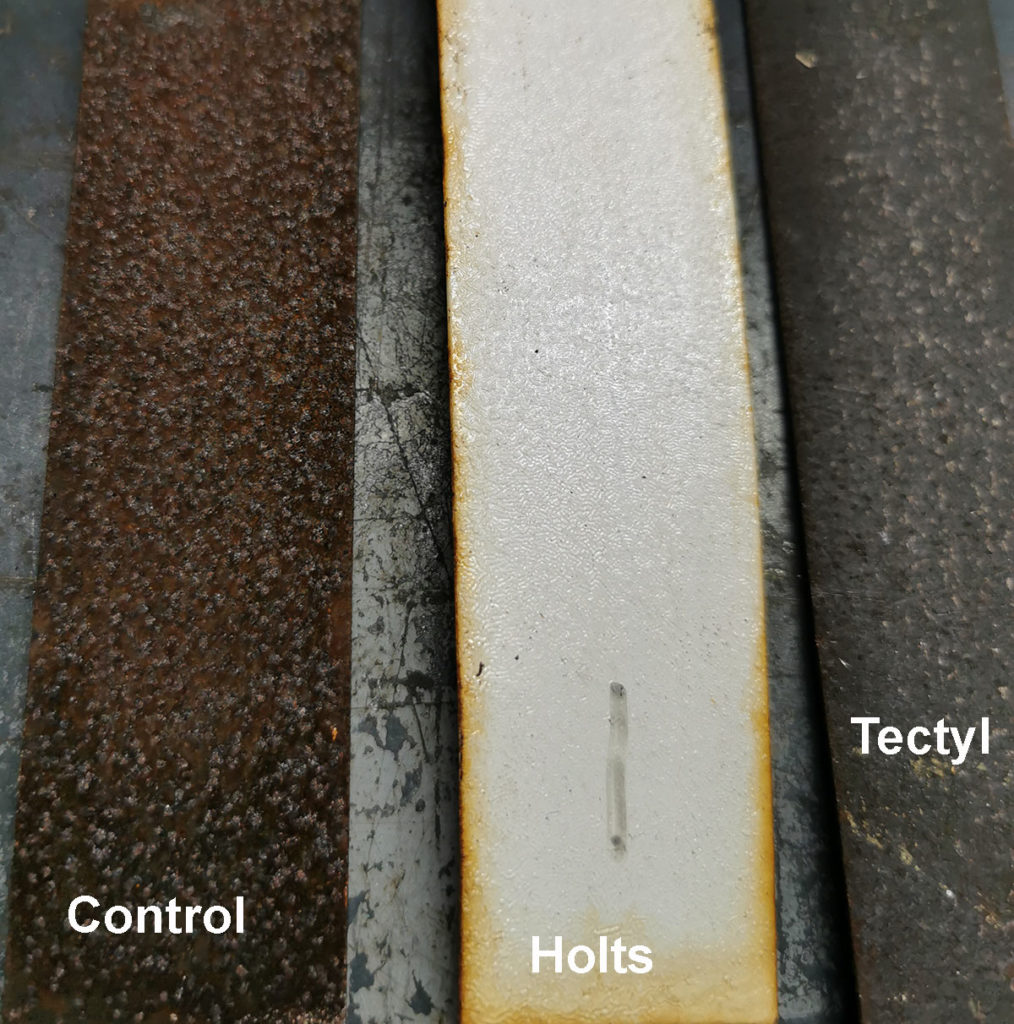

Untreated Control

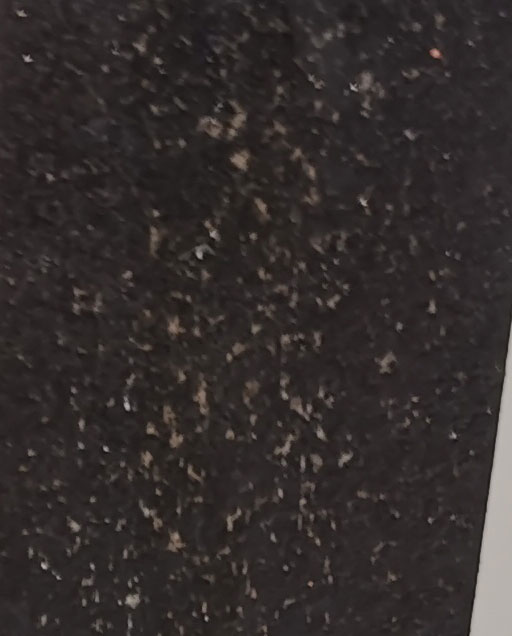

If I only look at the side without enamel then I can conclude after the first 2 weeks:

1. Of the water based solutions Holts is doing the best so far and NS4 and Corroseal the worst.

2. Duram DTM shows very good results for a normal paint which does not really claim to convert rust.

3. The solvent based Duram NS5 which is also not a rust converter but normal etch primer, protects better than the Duram NS1 and NS4 water based products which are both specifically promoted to “convert and stop rust”

4. Of the two waxes Tectyl is doing better

5. After the first two weeks Hammerite Direct to rust and Rust Rite are the winners. I am surprised to see that the normal Hammerite Direct to rust is actually performing better than the Hammerite Rustbeater.

1 September 2020

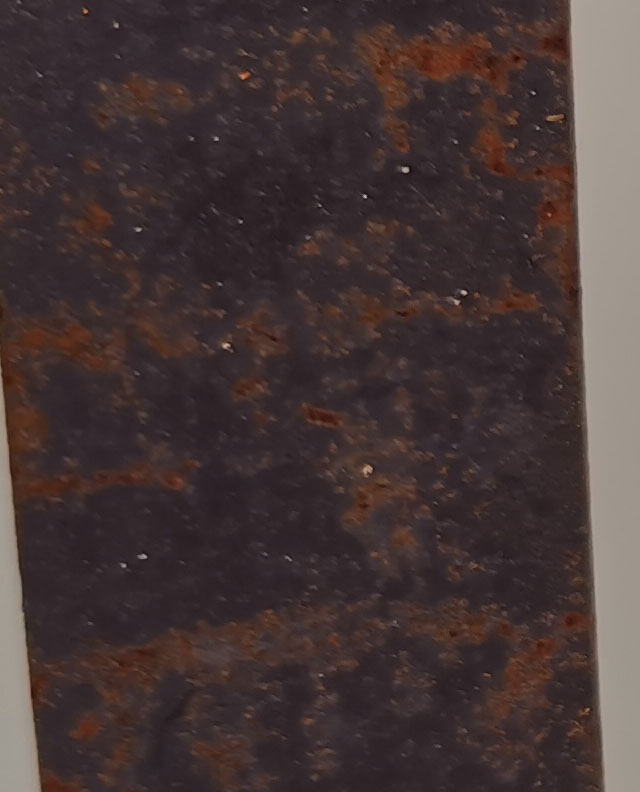

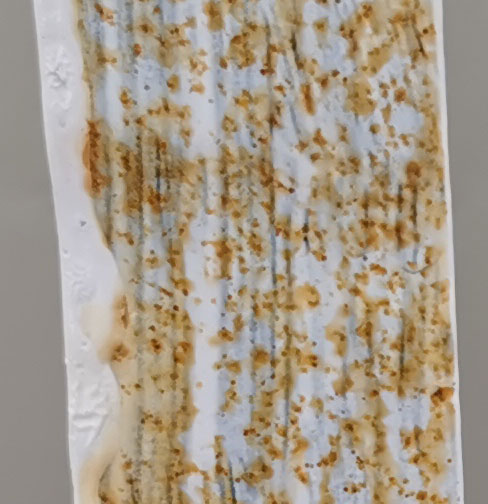

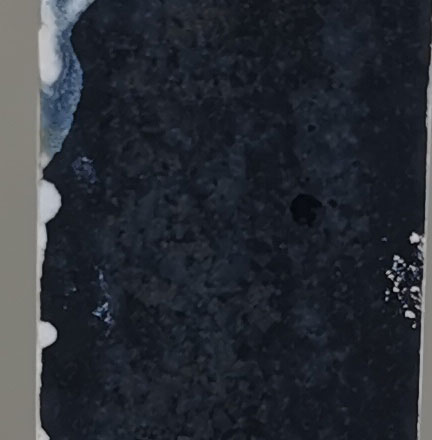

I removed the samples on 1 September 2020 and photographed them in the workshop

Remarks:

- On the unpainted side Tectyl did very well.

- Holts was also good but did not live up to the “stops all rust permanently” promise.

- Wurth did well within the first 2 weeks but afterwards fell out of the bus. The Wurth product is a much thinner wax than Tectyl and I think it just washed off.

- Interesting is that Hammerites Rust Buster did not perform well at all but Hammerite Direct to Metal was actually one of the best performing products in this test.

- Duram’s NS1, DTM and NS4 is crap when used alone. However DTM and NS4 did perform well on the painted side. NS5 outperforms the other products by far. NS1 and NS4 are clear indication that water based rust treatments do not work.

- In my opinion Rust Rite’s paint did very well. The “Hammered” texture worked against it. In the high areas it protected well, but in the lower areas (holes) of the texture the paint was too thin. Keep that in mind when you paint something with a “hammered” finish paint.

- Corroseal, the reason for this test, performed the worst of all products.

- On the painted side all product performed much better. Hammerite’s Direct to Metal and Rust Rite all in 1 metal coating performed the best by far. The pictures will show you why a top coat is very important.

Conclusion Test 1:

If your car shows signs of rust and you need to stop it, good old Tectyl will still be the best to treat areas where you cannot get it to remove the rust.

When you have a blister on the body you can remove all loose paint and rust and treat it with Holts. Then paint it with something like Hammerite Direct to Metal or Rust rite.

The products I often use in my workshop are (in no particular order):

NS5, Hammerite direct to metal Smooth Black, Rust Rite Smooth Black if I can get it, Holts and of course Tectyl. After this test I am allergic to a “hammered” paint finish.

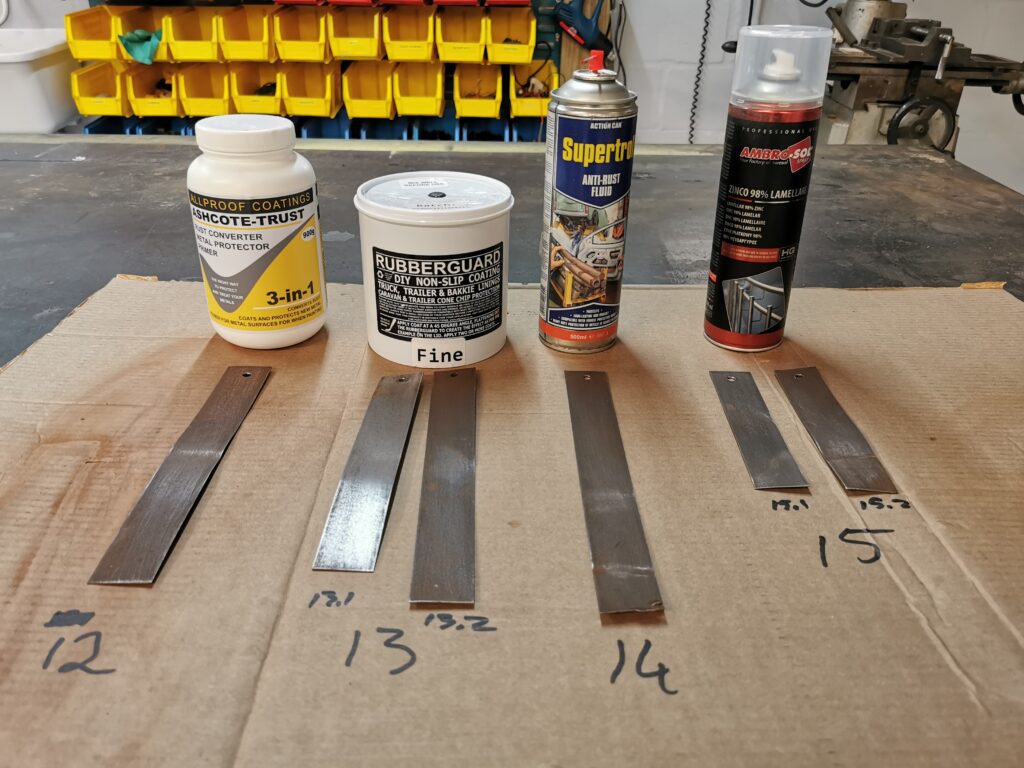

Test 2 – Feb 2021

I bought and received some more samples to test. The same procedure was followed.

Some of the samples I thoroughly cleaned and others I just cleaned with a steel brush. As per manufacturer instructions.

The new products were:

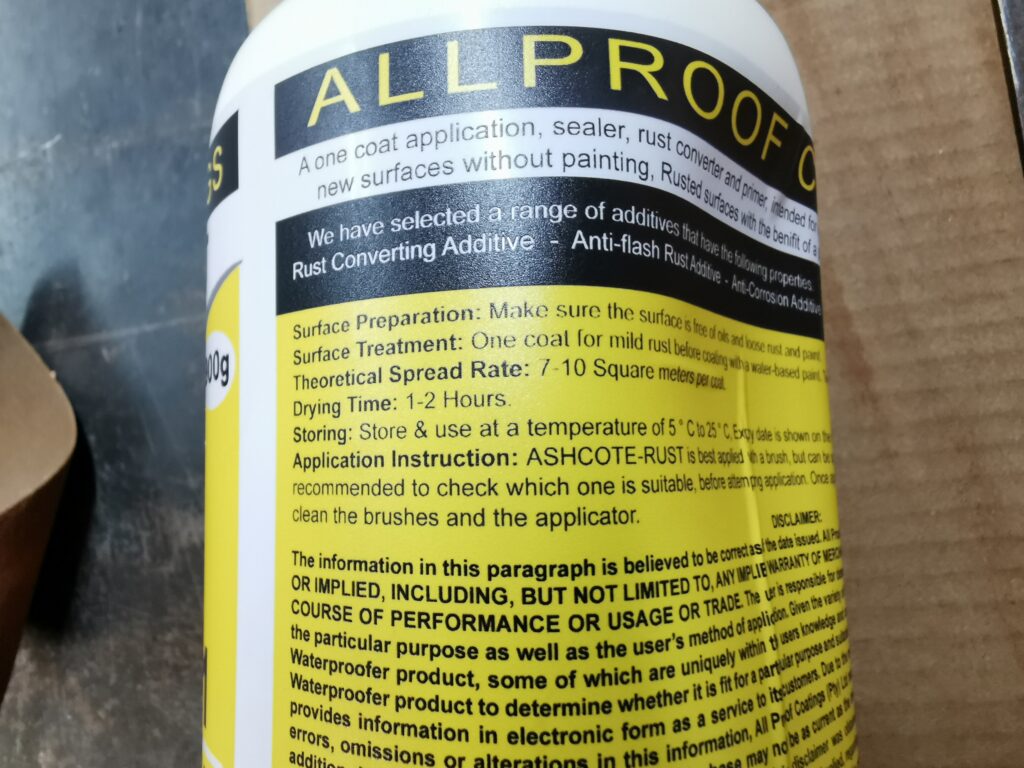

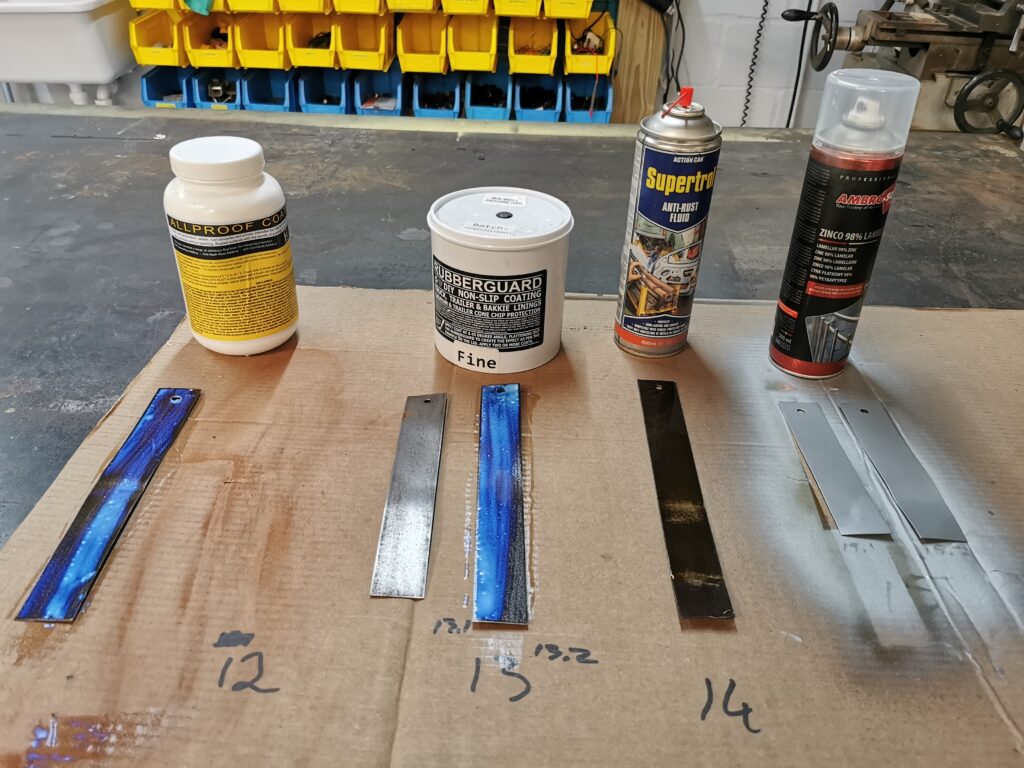

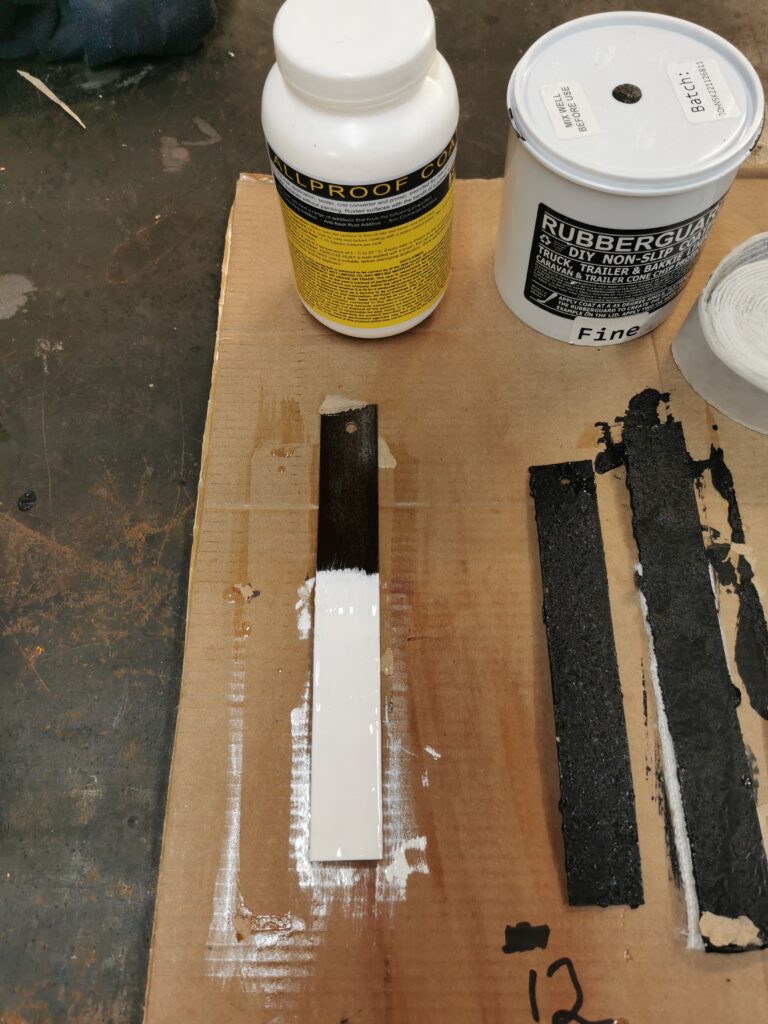

12 Ashcote-Trust Allproof coating

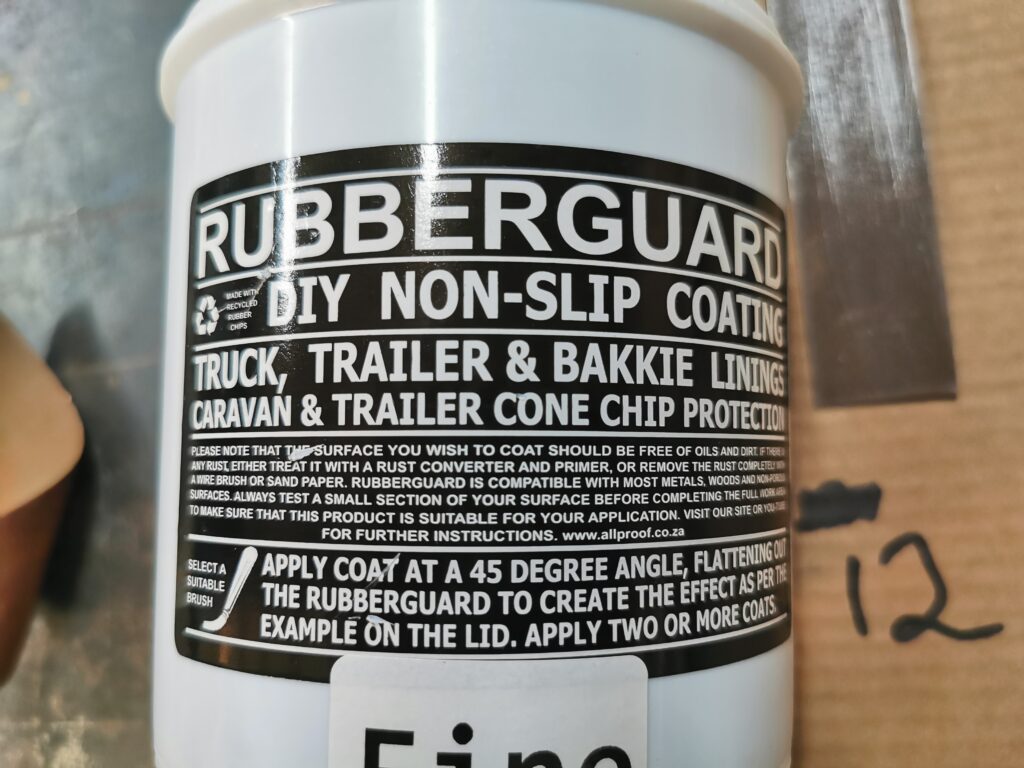

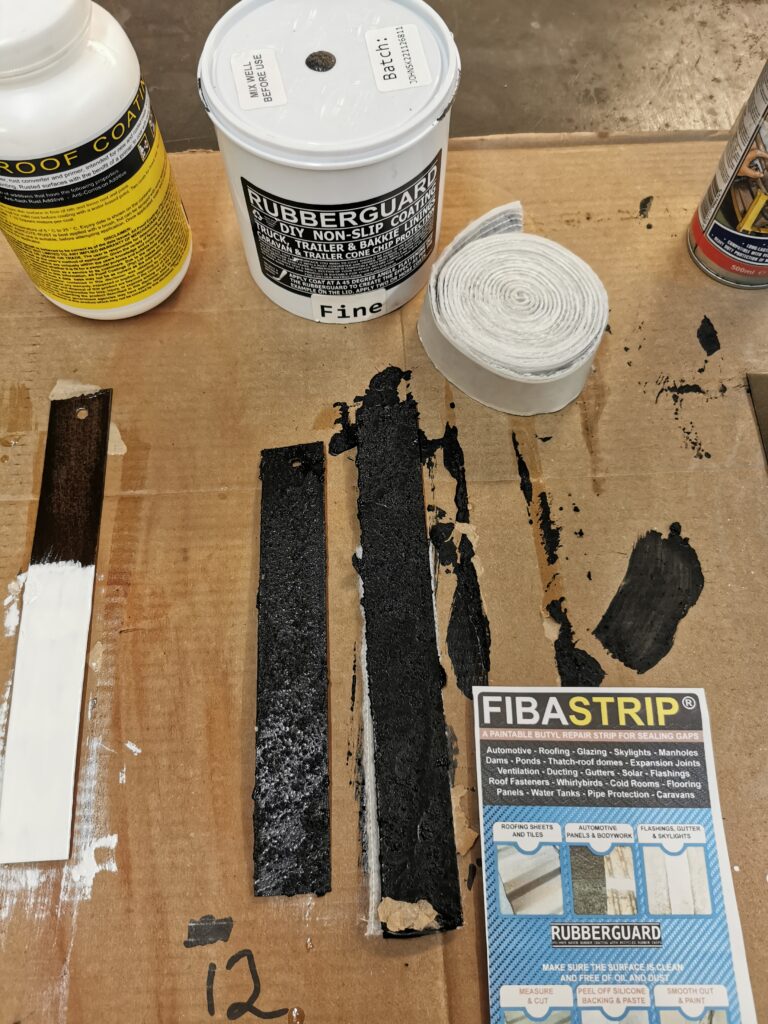

13 Rubberguard

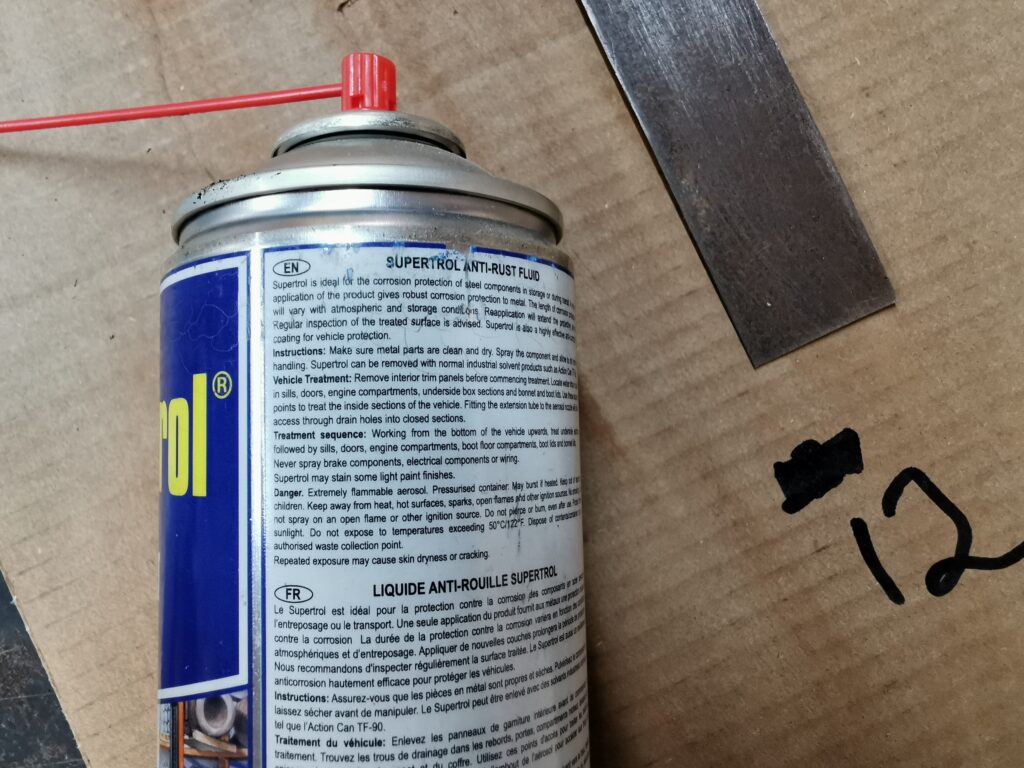

14 Supertrol Anti Rust Fluid

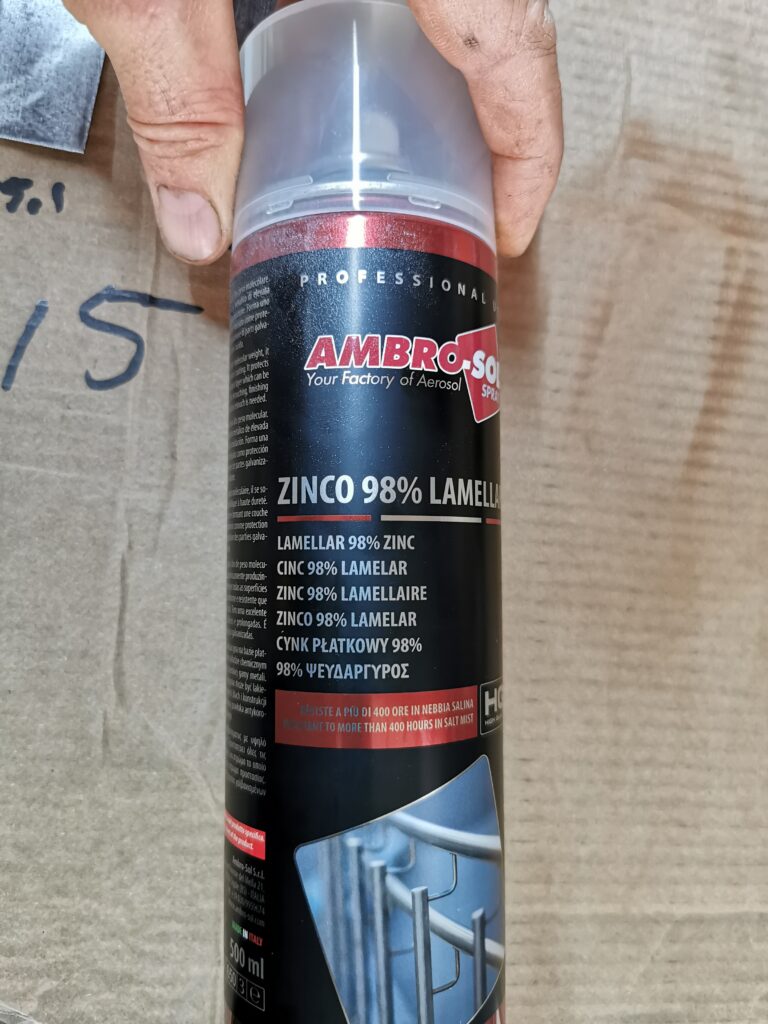

15 AmbroSol Zinc spray paint

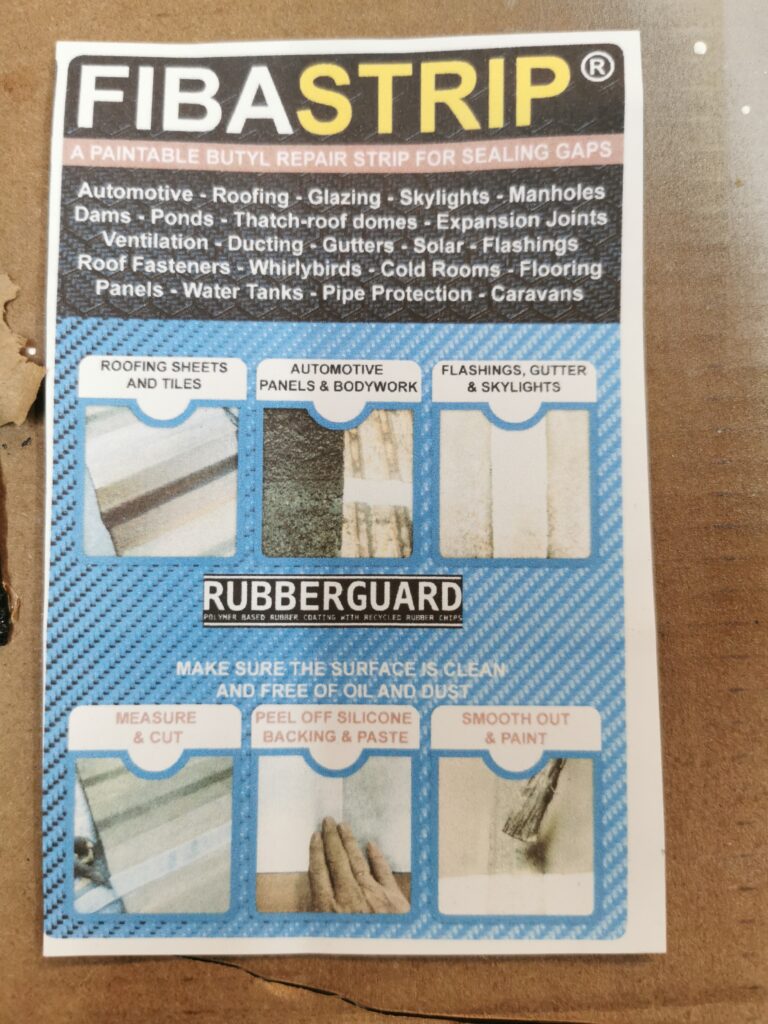

16 Fibastrip

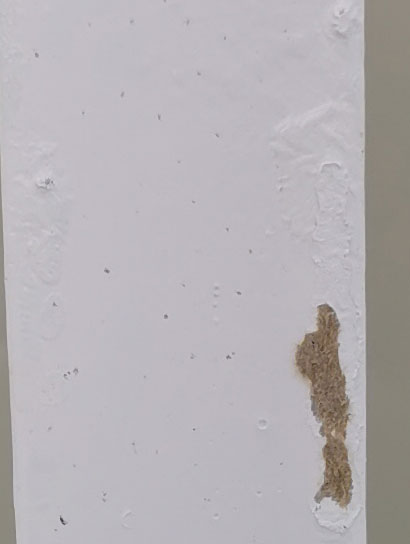

This time when the instructions said you can (or must) paint over the treatment, I painted half the plate and kept the other half unpainted.

I could not paint over product 14 Supertrol Anti Rust Fluid as it remains soft, pretty much like the Wurth product in test 1.

For products 13 Rubberguard and 15 Ambersol I used two strips, the one I sanded of almost all the rust and the other I just cleaned with a wire brush. The idea to see what will happen if you cannot remove all the rust, like in a real life restoration situation.

Products 12, 13 and 16 are manufactured in South Africa and although product 16 has nothing to do with corrosion treatment I added it to the back of the strip because they gave me a sample and it wont hurt to test it.

Weather conditions might be almost the same as last year. I am a month earlier than Test 1. Already we have dew in the evenings and in the mornings products are wet. SO I am sure we will get enough moisture to put the strips to the test. The strips are the same as last year’s strips, I still had some left..

On 13 Feb 2021 I hung the new samples, so now the waiting game can start.

Below pictures were taken on 23 March 2021

Below Pictures were taken on 13 May 2021.

On the back of samples 12, 13 and 14 you can see how well it preserve the metal compared to the other 3 strips which has nothing at the back.

Another interesting thing to note is the last 2 strip with the galv on. Note the rust on the edges. That is why you must always try to round the edges. Paint cannot cling to the sharp edges thus a sharp edge is always a weak point.

The rubberizing does not do well on its own. It is because you cannot get a 100% coverage with the rubberizing because of its roughness. Looking at the pic below I will most certainly first treat my metal before rubberizing.

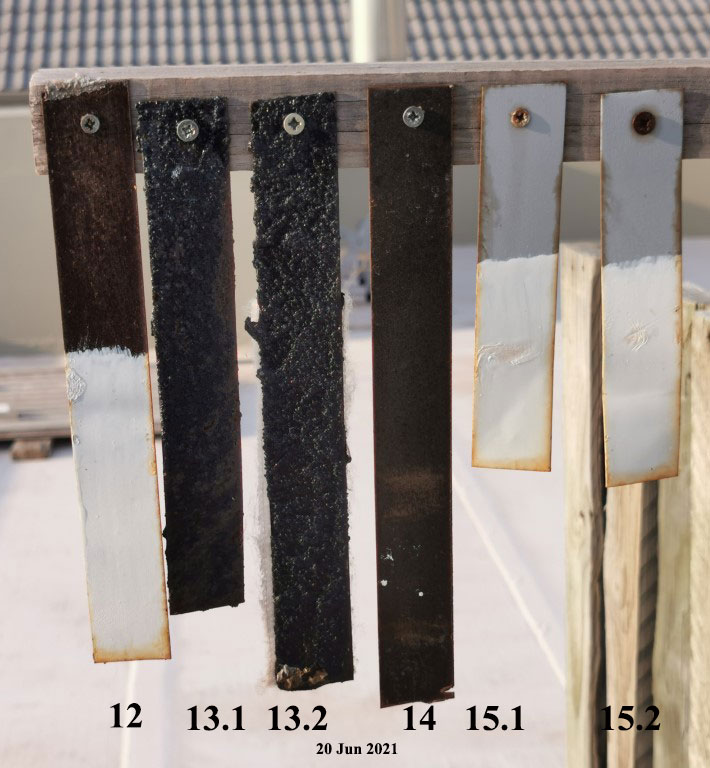

20 June 2021

Look at the rubberizing, remember 13.1 we sanded almost clean and 13.2 we just wire brushed, there is not much difference in the result. Also keep an eye on sample 14, the Supertol.

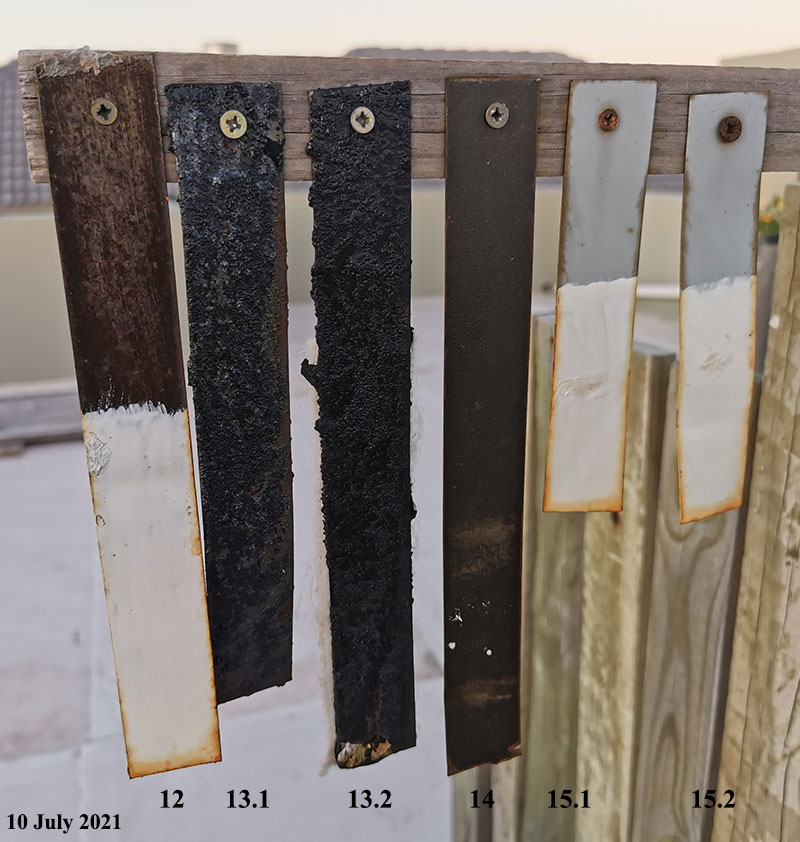

10 July 2021

The South African products and Supertol do not fail to amaze me. I am now using Ashcote-Trust Allproof coating, Rubberguard and Supertrol Anti Rust Fluid in my restorations. What I love about Ashcote’s Allproof is that it is 2K resistant. You can spray 2k over it and it wont wrinkle or peel. When you spray 2K on NS5, Hammerite or Rust Rite it peels off. If you did one of those 3 you must first spray a 1K primer over the NS5, Hammerite or Rust Rite and then only can you apply 2k. Even 2k filler primer will peel those 3 primers. BUT, with Ashcote you can just go on and spray your 2k primer then 2k base coat. I often use Ashcote now for the old double skin joints. I apply it thick with a brushes so the capilary forces can draw the liquid into the joint.

And then life happened and I did not take any pictures for a long time.

Went up to the roof again today and was amazed with the results. I wanted to end the test now but since I am so close to a full year since I started Test 2 I will give it time until it is exactly a year.

3 January 2022

This is the last picture in this series.